T7Y

TURNING AND MILLING CENTER

Spindle:Large Through-Hole,High Precision, High Speed,High Stability

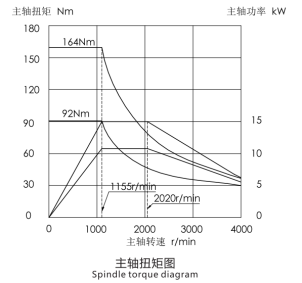

This machine adopts the form of a mechanical spindle.After precise dynamic balance correction,it has good rotational accuracy and stability,and strong vibration resistance.The spindleadopts high-speedangular contact ball bearing and cylindrical roller bearing structure,which has good rigidity and a speed of up to 4500r/min.

Machine Host:High Rigidity,High Anti Vibration Structure

T7Y CNC lathe adopts an integral 30°inclined bed structure,and adopts high-quality cast iron for multiple aging times to ensure the anti-deformation and anti-vibration ability of the basic parts;The large span design of the Z-axis guide rail improves the anti-deflection ability of the saddle;The integrated design of the saddle and theslide plate with the screw nut seat reduces the connection links and further enhances the force and vibration resistance of the displaced parts.This series of targeted design makes the machine have good vibration resistance,accuracy and long-term stability that far exceed the same level of models on the market.

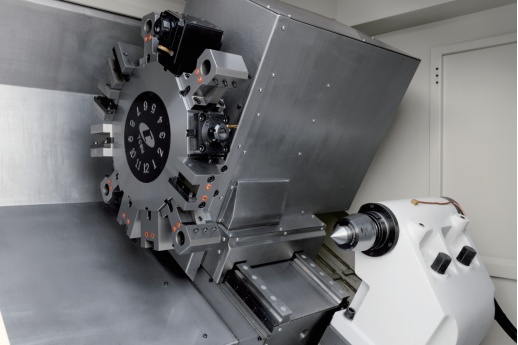

Tools:Quick Tool Change,Precise Positioning

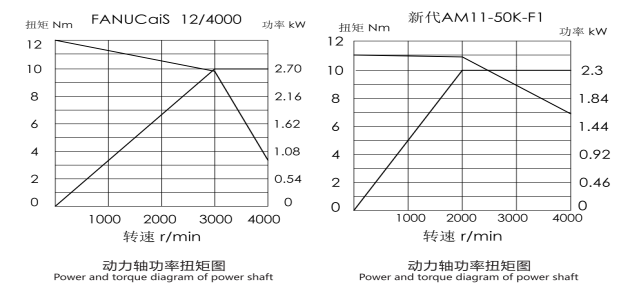

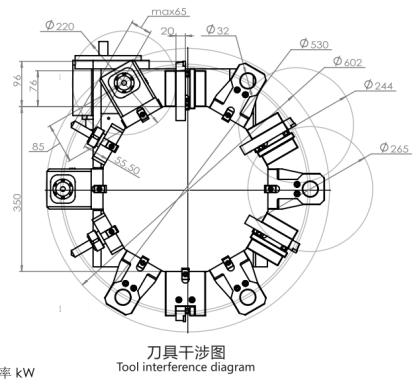

T7Y miling center adopts an orthogonal Y-axis (hard rail)withatwelve station power turret, servo indexing,tooth disc positioning,fast tool changing speed,accurate positioning,and meets the processing needs of most parts mlling and drilling in the market.

Feed:Accurate Positioning And High-Precision Feeding

The X-axis and Z-axis guide rails are made of high-precision linear roller-shaped rolling guides,and the Y-axis is in the form of hard rails,which has good vibration resistance and strong bearing capacity.The three-axis feed shaft adopts high-rigidity ball screws,which provide extremely high screw rigidity while ensuringthe feed accuracy.

MACHINE SPECIFICATION PARAMETERS

項(xiàng)目ITEM | T7Y標(biāo)配新代(選配發(fā)那科) Standard SYNTEC (Optional FANUC) | |

加工能力 Capacity | 床身上最大的回轉(zhuǎn)直徑 Max. swing diaover bed | φ650mm |

過(guò)床鞍最大回轉(zhuǎn)直徑 Swing over cross slide | φ350mm | |

最大的車削直徑 Max. turning diameter | φ350mm | |

最大的車削長(zhǎng)度 Max. turning length | 550mm | |

主軸 Spindle | 液壓卡盤(pán)尺寸 Hydraulic chuck dimensions | 8寸 |

主軸頭型式(ISO) Spindle nose | A2-6 | |

主軸轉(zhuǎn)速 Spindle speed | 45-4500r/min | |

主軸通孔直徑 Spindle borediameter | φ62mm | |

主軸可通過(guò)棒料直徑Through hole diameter | 卡盤(pán)(Chuck):φ51mm | |

主電機(jī)功率(連續(xù)/30分鐘) Spindlemotor (Continuous/30 minutes) | 11KW/15kw | |

刀架 Turret | 驅(qū)動(dòng)形式 Driving fom | 伺服動(dòng)力刀塔 Servo powered turret |

刀位數(shù) Number of stations | 12 | |

刀具尺寸(車削/鏜孔) Tool size (Turning/and boring) | 20×20/φ32mm | |

尾座 Tailstock | 尾座形式 Tailstock form | 液壓尾座Hydraulic tailstock |

套筒直徑 Tailstock dia | φ90mm | |

頂尖錐度 Center taper | MT No.5 | |

套筒行程 Tailstock quill travel | 100mm | |

尾座體最大行程Maximum stroke of tailstock body | 520mm | |

床鞍 Carriage | 傾斜角度 DEG Slant angle | 30° |

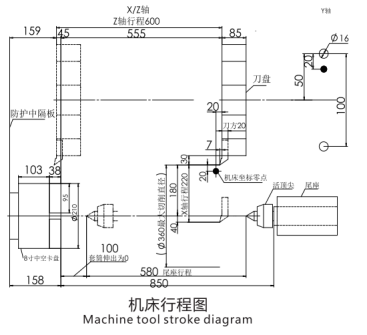

移動(dòng)距離 X/Y/Z travel | 220/100/600mm | |

進(jìn)給電機(jī)功率X/Y/Z Feed motor power X/Y/Z | 標(biāo)配2.4/1.1/2.4KW(FANUC1.8/1.8/1.8KW) | |

快速移動(dòng)速度X/Y/Z Rapid traverse rare X/Y/Z | 20/10/24m/min | |

最大進(jìn)給速度Max.imun feed speed | 8m/min | |

滾珠絲杠直徑X/Y/Z Ball screw diameter X/Y/Z | φ32×10/φ32×10/φ40×12mm | |

冷卻 Cooling | 電機(jī)功率/揚(yáng)程 Motor Power/lift | 550W/40KW/M |

冷卻箱容積 Cooling tank volume | 150L | |

其它 Others | 電源容量Required electric Power | 25KVA |

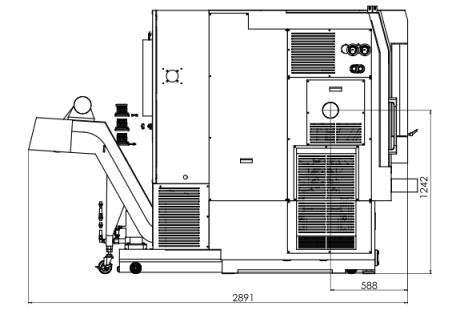

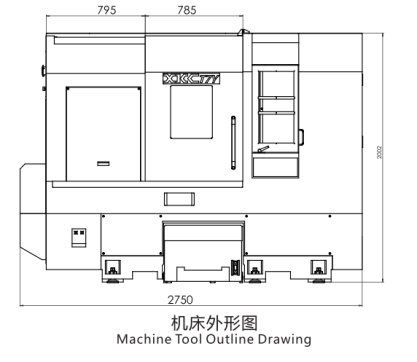

機(jī)床尺寸(長(zhǎng)×寬×高)Floor Space | 2750×2020×2100mm | |

機(jī)床重量 Mass of machine | 約 5000kg about 5000kg | |