XKC-HTN50 series CNC lathe is a set of high rigidity, high strength, high precision, high reliability, full function CNC lathe in a high power. To maintain accuracy, high production efficiency, and strong operability, beautiful appearance, convenient operation, good waterproof effect, the front side of the water tank can be pulled out. Chip removing device has the advantages of convenient installation, saving space. The main motor adopts FANUC servo spindle motor, reducer the spindle torque is more robust, can achieve high strength cutting. Two imported linear guide rail, improve the machining accuracy and high feed performance. Suitable for high efficiency, high precision, disc parts and long short axis Processing.

Main machine tool design features:

1.High rigidity Spindle-Machine tool adopts box-type spindle, imported ultra-high precision spindle bearing, ensures high rigidity and lasting precision of spindle, spindle runout < 3 μ m.

2.Numerical control system - the use of FANUC numerical control system to make the machine with high stability.

3.High efficiency processing machine spindle maximum speed 4500 revolutions / minutes, X, Y axis fast moving speed up to 20 meters / minute. Automatic feeder can be configured to achieve high-speed, efficient automatic processing.

4.High rigidity servo turret-High rigidity and accuracy servo turret 12 tools from Italy,that change cutters with high intensity ,high speed,stable,accurate,can substantially save processing time.Tool size:25mm&?40mm.

5.High precision feed -Feed all shaft servo drive, using imported high precision ball wire rod, to ensure machining accuracy and long time accuracy.

6.Bed structure - High rigid castings 45 degrees overall inclined bed body structure, fluency, compact structure, beautiful shape.

7.Hydraulic tail seat - Hydraulic tail seat, tail guide rail removable, flexible configuration, greatly improve the machining precision and efficiency of shaft parts, greatly save processing time.

Machine Specifications

Range of work | Swing over bed | ?520mm |

Swing over cross slide | ?260mm | |

Max. turning diameter | ?380mm | |

Maximum turning length | 750mm | |

Principal axis | Spindle max. speed | 4500rpm |

Max through rod diameter | ?51mm | |

Chuck size | 8寸inch | |

Type of spindle nose | A2-6 | |

Spindle bore | ?62mm | |

Output power (continuous /30min) | 15KW/18.5KW | |

Tool turret | Turret type | Servo cutter tower |

Cutting tool capacity | 12 | |

Tool changing time | 0.26S/0.5S | |

Tool size (turning / boring) | 25/ ?40mm | |

Tailstock | Tailstock | Movable hydraulic tail seat |

Tailstock quill taper hole | MT5 | |

Sleeve diameter / stroke | ?90mm/90mm | |

Maximum movement of tailstock | 600mm | |

Travel feed | X axis travel | 220mm |

Z axis travel | 770mm | |

Maximum speed of X/Z axis | 20m/min | |

Coolant system | Volume | 160L |

Coolant motor power | 180W | |

System | Controller | FANUC Oi-mate TD |

Others | Power capacity | 25KWV |

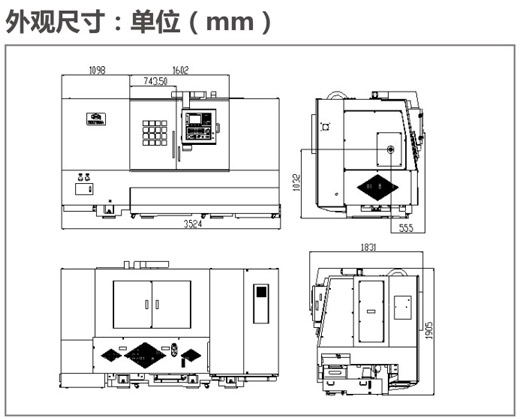

Machine tool size (length * width *height) | 3524*1831*1905mm | |

Weight of Machine | About 5,000 KG |

Standard layout

Hydraulic pressure system | 1 Set |

Coolant passage | 1 Set |

Automatic slide surface lubricate | 1 Set |

12 Position servo knife tower | 1 Set |

O.D Tool holders | 1 Set |

I.D Tool holders | 3 pieces |

Pads for tool holders | 12 pieces |

Hydraulic tailstock | 1 pieces |

Revolving centre | 1 Set |

Maintenance tools | 1 Set |

Lighting unit | 1 Set |

Tri coloured lantern | 1 pieces |

Machine base | 6 pieces |

Optional configuration

Hydraulic chuck (10 inch) |

The hydraulic collet (6 inch) |

Automatic rod conveyor |

Automatic feeding device |

Pneumatic system |

Real chuck |

Chain plate type automatic chip ejector, iron chip truck |

Automatic cutter adjusting instrument |